Outsourcing POS Manufacturing to China

If you’re looking to outsource your point of sale production to China, here’s what you need to be thinking about

China has developed a robust outsourcing industry that has led to strong ties with many markets around the world, including the United Kingdom. In many ways, it’s a no brainer for many UK companies to look East for manufacturing partners.

Outsourcing your manufacturing to China provides many advantages. Doing so can cut production costs and allow you to take advantage of adding production capabilities that lie outside your own.

Despite the obvious attractions, you still need to carefully consider the practicality of outsourcing your project. Some of the key factors that should influence your decision are around the certainty and reliability of the process so that you can understand the true cost benefits.

Here’s a few things to think about if you looking to outsource manufacturing to the Far East.

It’s important to focus on good communication during the design phase

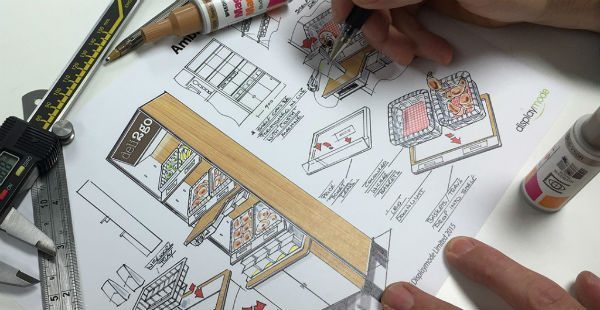

Working with offshore manufacturers adds complexity to collaboration during the design phase. Yet, this aspect is critical when it comes to POP display designs. Working closely with a local manufacturer gives you an opportunity to achieve your design objectives. The service provider needs to understand your overall marketing objectives. Doing so makes it easier to incorporate your vision into the design.

The benefit of UK firms is that they understand local consumers’ in-store behaviour and the retail environment better than off-shore entities. This allows the manufacturer to create appealing retail marketing displays.

Time zone differences and communication challenges are inherent to outsourcing to China. You lack the option to simply drive to the manufacturer’s premises or make a domestic phone call to explain any design changes or collect prototypes. Be clear and consistent in your communication. Tend towards communicating until the point you bore yourself but are 100% certain that you are understood by your manufacturing partner and have their full commitment.

Don’t forget about the need for prototyping

In some cases, the design phase requires the production of full-scale prototypes. This stage enables you to assess various factors, including aesthetics, functionality and suitability of materials. It allows last-minute improvements prior to full production. Yet, the implementation of this stage is prolonged when outsourcing the manufacturing. As a result, you may tempted to skip this stage, which may compromise product quality.

Prototyping gives you assurances that the aesthetically pleasing design you envisioned can be built. Lack of practicality leads to production issues. Meanwhile, prototyping can help save money. The process may reveal material overuse; thus the design may be able to be value engineered or the converse, might need to be strengthened if not robust enough.

Getting materials selection and use right

Offshore POS display manufacturers can be found to use unsuitable materials due to wrong or misunderstood specifications – sometimes they make a questionable decision to drive out further cost. The issues often come to light when production is completed and by this stage it’s too late. This compromises the durability and structural integrity of the stands and your reputation with your customers. Material selection requires experience and detailed knowledge about application, environment as well as intended service life.

If you don’t want to travel yourself, there are agents that offer quality control services to make sure the materials being used are suitable. They can also sign-off production on your behalf. These agents aren’t easy to find and add to the cost of the project but if you find a good one they can be the difference between success and failure.

Time and reliability challenges in outsourcing production

Offshore manufacturers may miss deadlines due to lack of communication or through over trading and not coping with their order book. In some cases, what you think is a manufacturer is an agent that simply connects you to a factory, manages the process and takes a cut. This can be problematic if you are relying on the partner for technical advice.

Often, with a Chinese manufacturer, there is a requirement for higher minimum volume and pre-payment – 50% upfront and 50% on dispatch isn’t unusual. Add in the 4-8 weeks of extended lead time when shipping by boat and you start to erode the cost savings by the cost of cash tied up in the deal.

The argument for outsourcing is a strong one and works well for many companies. However, the benefits must be considered alongside the downsides. Often UK firms end up being a more viable option when aiming for good quality, responsiveness and reliability.

DisplayMode can help you realise your retail display objectives. Our team of experts can provide advice on material selection, prototyping and more. For more information, get in touch with us today.