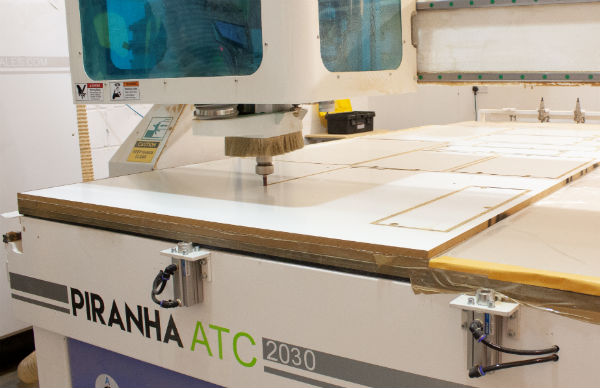

Factory Investment: CNC Machine for POP Manufacturing

Our new CNC machine bringing benefits to our customers

We recently made a six-figure investment to our factory in the UK with a new CNC machine. This has brought huge benefits to our capabilities at DisplayMode, and the quality of product and speed at which we can produce work for our customers.

What is a CNC machine?

CNC (computer numerical control) machining refers to the use of computers to control machine tools in the manufacturing sector. Without CNC, manufacturing is reliant on manual or mechanical control. With CNC we automate much of the manufacturing process with the CNC machine working directly from the CAD (computer aided design).

CNC machining is a massive advance in the manufacturing world, allowing more accurate and speedier output.

Highlights of functional capabilities

10 head multi-change – there is a cartridge where all the heads are kept, the machine swaps these very quickly as needed, reducing downtime. Designs can be more intricate, we have the capability to cut to the edge and more flexibility on where to place holes. These improvements enable our point of purchase (POP) output to be as close to the original design as possible and our designers do not need to compromise their ideas as much at the design stage

Oscillating knife – can work with cardboard and other materials giving us versatility. We have improved scope in the designs we can manufacture and are able to reduce outsourcing; we can go up to the edges, and work with a much wider range of materials including those that are very flexible such as polypropylene, thin PVC and rigid card

Manufacture our own tools – state of the art technology provides us with added scope. When we work with customers there can be a need for new tooling which can bring considerable delays to project timelines. With the CNC we can make our own tools for other production processes such as vacuum forming. This one investment has extended our capabilities across the factory with improved results across the board

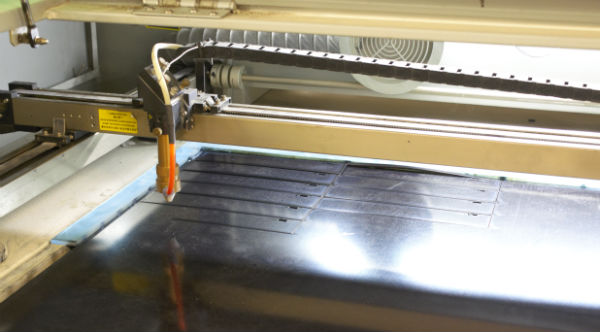

A note on lasers

Lasers certainly have their place in the world of manufacturing, and we ourselves use them, but in certain situations CNC has a distinct advantage. Lasering creates issues for materials that are pre-printed; the lasers often cause scorching or crazing which means, for example, that artwork cannot be taken all the way to the edge. This is not the case with CNC. CNC gives us additional capability and flexibility.

What does a CNC machine do for our customers?

Saves time – working from CAD means we reduce the time required to set up machinery for new designs bringing a faster turnaround and lower costs on projects for our customers

More versatility – CNC gives us the scope to work with larger formats, giving our customers more flexibility on their designs. We can take on projects that were previously unfeasible, and we can work with less compromise or the need to find alternatives which could sometimes increase costs

Better control – unlike lasers, CNC enables us to work with bleeds and trim accordingly and as needed; we can cut right to the edges which gives our designers more flexibility and avoids workarounds having to be designed in.

Key takeawayThe CNC machine has brought huge productivity gains to our factory. We have reduced downtime, improved processing speeds, and are producing the highest quality product with an intricate level of detail for our customers. Our improvements have brought cost savings which we are able to pass on to our customers, and they also benefit from our improved capabilities, superior quality and quicker timescales.